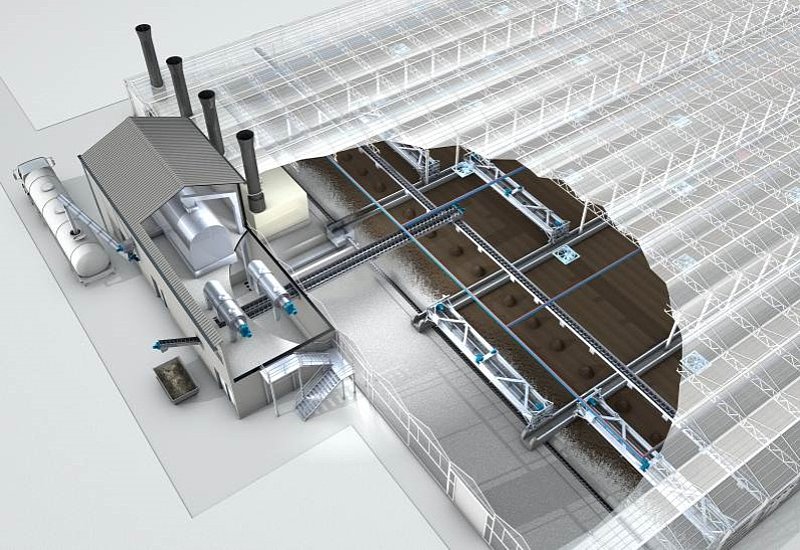

Our options to meet specific needs a floor heating system to optimize drying cycles to ensure consistent performance throughout the year solia may be fitted with an additional source of energy.

Solar sludge drying systems.

The solar sludge drying and thermal drying systems help sludge from going to landfills at a time when new ones are not getting ec.

Sludge can be dried in batches using a semi continuous process by means of a fully.

The sludge is transported.

Common ways of disposal are agricultural spreading as fertilizer land re cultivation landfill and co combustion of dewatered sludge.

Of solar sludge drying more economical more ecological.

The solar sludge drying systems can be erected on a variety of flat or inclined surfaces in a range of climates and can be adapted to retrofit existing drying beds.

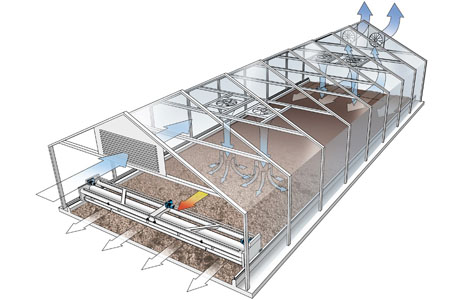

Solar energy is used to extract water from sewage sludge a simple and cheap process that not only reduces the sludge considerably in terms of volume but also saves truck mileage and c0 2 emissions.

The heat from the treated effluent is extracted by a heat.

Further the existing ones are reaching capacity and it is important to repurpose this sludge into useful by products for being used in a cement factory.

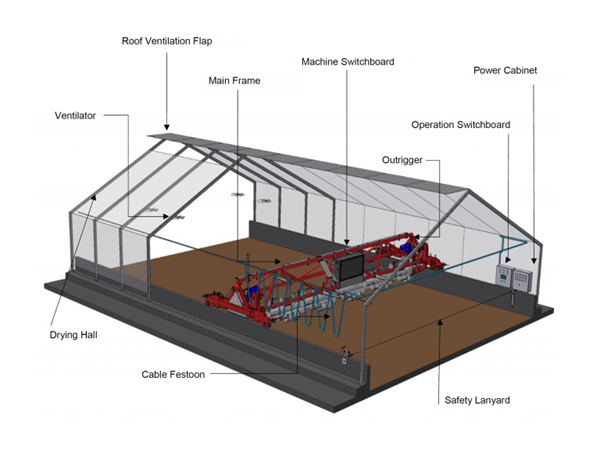

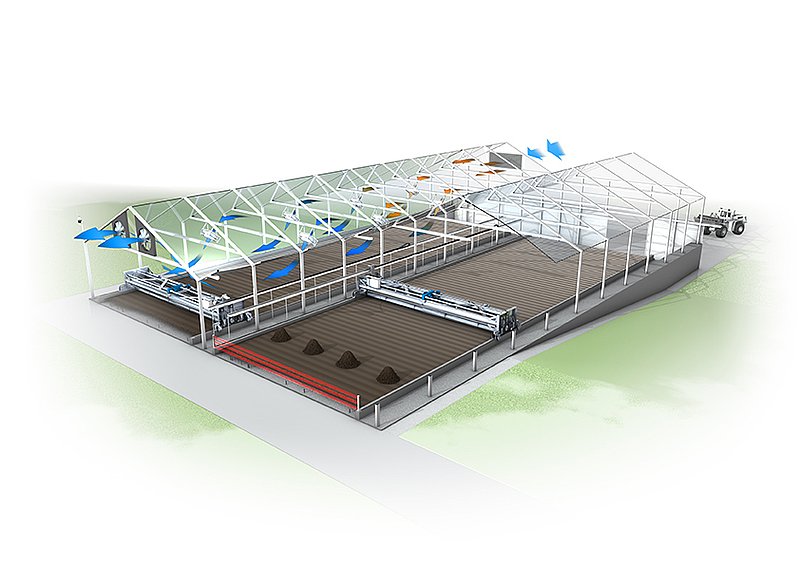

Solar drying system is based on the greenhouse effect where sludge is spread into a greenhouse and mixed mechanically with a mixing device periodically.

After dewatering the system is able to dry the sludge up to 90 dry solid to reach the energy values between 9 to.

Height of the sludge should be around 30 cm to reach max.

The huber solar regenerative sludge dryer srt is able to meet the most different specific customer requirements whether as a pure solar dryer or all year round dryer operated with additional heat.

Solar sludge drying is an ideal method of reducing sludge volumes and disposal costs particularly in the australian climate.

The world s largest solar sludge drying plant was built by our partner the market leader thermo system in palma de mallorca.

The combined sludge turning and transporting system is at the heart of the drying plant.

Parkson says a consistent end product is always produced within a specific time frame with changing weather conditions having little effect on results.

Contracting entity and operator was the disposer tirme sa who also operates a waste incineration plant on site where the dried sewage sludge is incinerated.

Solar sludge drying excels in fulfilling key economic and environmental goals.

Sewage sludge disposal is a hot topic of discussion topic since years.