Zhonghuan semiconductor another wafer giant unveiled its latest wafer product the new m12 size in august 2019.

Solar wafer sizes.

Zhonghuan said a 60 cell pv module with this impressively enlarged wafer would easily boast module power output of more than 600 wp.

Although there have been many adjustments over the years the continuity has unfortunately disappeared.

In recent months countless new wafer sizes have appeared on the market.

In inches this translates to about 5 9 to 18 inches.

Electronics use wafer sizes from 100 450 mm diameter.

By the end of 2013 a number of producers jointly issued the standards for m2 156 75mm x 156 75mm p type mono wafers 205mm diameter silicon ingot and m2 156 75mm x 156 75mm p type mono.

The common sizes of wafers today run from 150 millimeters to 450 millimeters.

The wafer is the starting material for the production of crystalline solar cells which is only about 200 µm thick.

After 2010 156mm x 156mm wafers increasingly became the popular choice lower cost per watt for p type monocrystalline and multicrystalline wafer sizes.

Seven solar manufacturers including tier 1 players have signed up to a joint initiative aiming to establish a new standard size for silicon wafers at 182mm x 182mm.

The size of wafers for photovoltaics is 100 200 mm square and the thickness is 100 500 μm.

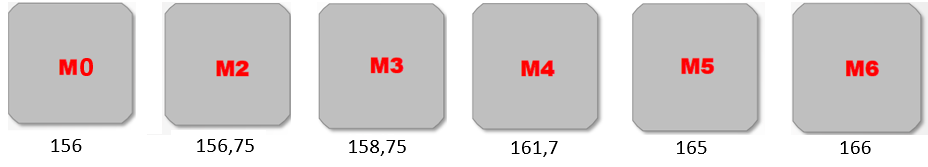

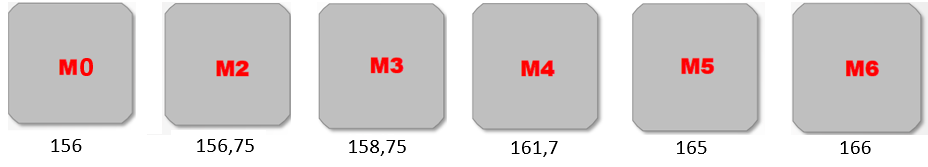

Jinkosolar began producing modules with 158 75 mm side length in 2018 lg went even further with 161 75 mm in as early as 2017 whereas canadian solar pushed their multicrystalline technology with 166 75 mm side length cells.

It features a much bigger size of 210 mm in length and 295 mm on the diagonal.

The boule is then sliced with a wafer saw a type of wire saw and polished to form wafers.

Then came the m4 wafer 161 75 mm around 2016 and the last few years have seen increased interest in even larger wafers with m6 166 mm m10 182 mm.

Why wafer size matter.

M1 m 2 m3 m4 m5 m6 m12 solar wafer and solar cell sizes m1 m2 m3 m4 m5 m6 and m12 are standard different wafer sizes used in the solar cell production process.

The largest wafers made have a diameter of 450 mm but are not yet in general use.

The demand for wafers has exponentially increased over the past two decades due to the increase in the production and sale of pv systems smartphones and more.

In last weeks pv tech s techtalk series webinar with ja solar highlighted at length the various wafer sizes on the market and what these sizes meant to pv power plant projects as well as launch.

In 2012 the m0 wafer 156 mm was introduced with the m2 wafer 156 75 mm eventually becoming the dominant size.

Although m2 wafers are easy to integrate even larger wafer sizes are beginning to be used to obtain 400 w plus modules.